In a world where ideas are born faster than a cat can knock over a glass of water, rapid prototyping 3D printing is the superhero we didn’t know we needed. It’s like having a magic wand that transforms sketches into tangible objects quicker than you can say “where’s my coffee?” Whether it’s for product design, engineering, or just impressing your friends with your new hobby, this technology is revolutionizing the way creators bring their visions to life.

Imagine crafting a prototype in hours instead of weeks, all while saving resources and avoiding the dreaded “oops, I did it again” moment. With rapid prototyping, innovation isn’t just a buzzword; it’s a reality. Dive into the world of 3D printing and discover how this game-changing approach can turn your wildest ideas into reality—without the need for a DeLorean or a flux capacitor.

Table of Contents

ToggleOverview of Rapid Prototyping 3D Printing

Rapid prototyping through 3D printing allows designers and engineers to create physical prototypes quickly and efficiently. This technology streamlines the design process, transforming concepts into tangible forms in a matter of hours rather than weeks. Designers enjoy the flexibility to iterate on their ideas frequently, enabling them to refine product features swiftly based on feedback.

Cost-efficiency characterizes rapid prototyping. Traditional methods often require expensive materials and long production times. In contrast, 3D printing reduces waste, as it builds objects layer by layer. This approach conserves materials and helps companies save on production costs.

Diverse industries benefit from rapid prototyping. In automotive sectors, manufacturers design and test vehicle components faster than ever before. The healthcare industry employs 3D printing for custom medical devices, ensuring a patient-specific fit. Additionally, the consumer goods market utilizes rapid prototyping to innovate product designs rapidly.

Collaboration is enhanced by rapid prototyping as well. Team members can visualize ideas in real time, fostering better communication during the design phase. This interaction leads to more informed decision-making, encouraging creativity and problem-solving.

Integration with software is another aspect that enhances rapid prototyping. Software tools allow for precise modeling, ensuring that the 3D printed prototype closely resembles the intended design. As a result, users can identify potential issues early in the development process.

Ultimately, rapid prototyping through 3D printing represents a paradigm shift in product development. By enabling faster iterations, reducing costs, and improving collaboration, this technology paves the way for more efficient innovation.

Advantages of Rapid Prototyping 3D Printing

Rapid prototyping through 3D printing offers significant advantages that transform product development across various industries.

Speed and Efficiency

Speed defines rapid prototyping. This technology shortens the prototype creation process from weeks to hours, enabling swift design iterations. Designers and engineers quickly translate ideas into tangible objects, facilitating immediate feedback. Efficiency improves with the ability to test and modify prototypes in real-time. Many teams can meet tight project deadlines, adjusting designs based on user input without extensive delays. Iterative testing enhances product performance, ensuring that final designs meet customer demands effectively.

Cost-Effectiveness

Cost-effectiveness highlights another benefit of rapid prototyping. 3D printing minimizes material waste, as it only uses the necessary amount of resources for each prototype. This process significantly lowers overall production costs compared to traditional manufacturing methods. Industries notice substantial savings through less expensive materials and reduced labor hours. Furthermore, the ability to quickly produce multiple prototypes allows for broader testing without overwhelming budgets. Companies can invest resources in innovative design rather than lengthy production cycles, driving efficiency while maximizing return on investment.

Applications of Rapid Prototyping 3D Printing

Rapid prototyping through 3D printing finds extensive applications across multiple industries, enhancing efficiency and innovation.

Product Design and Development

Product design benefits from rapid prototyping by allowing designers to create and test multiple iterations quickly. Feedback becomes actionable, enabling teams to refine concepts before final production. Companies can explore various materials and forms with minimal investment. Faster turnaround times eliminate long waiting periods, accelerating the entire development process. This direct relationship between design and prototyping fosters creativity, empowering teams to push boundaries and invent unique solutions.

Healthcare and Medical Devices

In healthcare, 3D printing revolutionizes the creation of custom medical devices and implants. Surgeons can utilize patient-specific anatomical models for pre-surgery planning, leading to improved outcomes. Rapid prototyping facilitates the design of prosthetics that fit more comfortably, enhancing patient satisfaction. Cost reduction is evident as companies produce low-volume customized devices without heavy tooling expenses. Moreover, the speed of producing medical models aids in testing new therapies and techniques effectively.

Technologies Used in Rapid Prototyping 3D Printing

Rapid prototyping employs various technologies, each contributing unique advantages to the 3D printing process. These methods enhance efficiency and precision in product development.

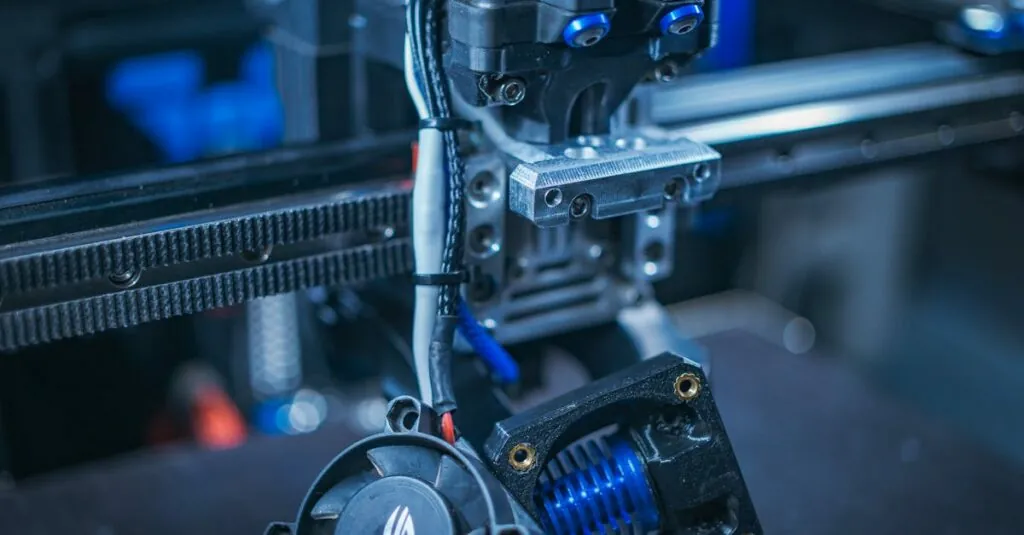

Fused Deposition Modeling (FDM)

Fused Deposition Modeling stands as one of the most widely utilized techniques in rapid prototyping. It operates by extruding heated thermoplastic material through a nozzle, layer by layer, to construct an object. Industries appreciate FDM for its cost-effectiveness and accessibility. Diverse materials, including ABS and PLA, make it versatile for different applications. Designers favor FDM when creating functional prototypes, as it successfully captures intricate details while maintaining structural integrity.

Stereolithography (SLA)

Stereolithography offers exceptional detail and surface finish in rapid prototyping. This technology utilizes a high-powered laser to cure liquid resin into solid layers. Industries such as jewelry and dental frequently employ SLA due to its capability for high-resolution parts. Quick turnaround times and precise customization cater to specific design demands. SLA also enables the creation of complex geometries, making it an ideal choice for prototypes requiring fine detail and accuracy.

Selective Laser Sintering (SLS)

Selective Laser Sintering utilizes a laser to fuse powdered material into solid forms, allowing for robust prototypes. This method accommodates various materials, including plastic and metal, expanding its application scope. Engineers appreciate SLS for its ability to produce durable, functional prototypes with minimal support structures. The technology suits complex designs, making intricate shapes achievable without compromising strength. Quick production times alongside effective material usage elevate SLS as a preferred method in industries like aerospace and automotive.

Challenges and Limitations

Rapid prototyping through 3D printing faces several challenges that impact its broader adoption. Material limitations present one of the primary obstacles. Current 3D printing materials, such as plastics and metals, can lack the strength or durability required for certain applications.

Inconsistencies in quality often arise during the printing process. Variations in temperature or printer calibration frequently lead to defects, affecting prototype performance. Maintaining consistent quality demands precise control over printing parameters and conditions.

Production speed can also be a constraint. While 3D printing significantly accelerates prototyping, large-scale production remains slower compared to traditional manufacturing techniques. This slower pace poses challenges for businesses seeking to meet high-volume demand rapidly.

Financial implications emerge as another concern. Initial investments in advanced 3D printers and materials can deter smaller companies from embracing the technology. Budget considerations impact the feasibility of prototyping projects, particularly for organizations with tight financial constraints.

Intellectual property risks must not be overlooked. Rapid prototyping makes it easier to replicate designs, raising concerns about design theft and piracy. Protecting proprietary designs requires careful attention to legal measures and security protocols.

Lastly, skill gaps among users present challenges. Proficiency in operating advanced 3D printers and optimizing designs necessitates specialized knowledge. Limited access to training can hinder the ability of teams to fully leverage rapid prototyping capabilities.

Addressing these challenges is vital for fully realizing the potential of rapid prototyping through 3D printing. Each limitation underscores the importance of continuous advancements in materials, technology, and training to enhance the efficacy and adoption of this transformative process.

Conclusion

Rapid prototyping through 3D printing is reshaping the landscape of product development. Its ability to accelerate design iterations and enhance collaboration empowers teams to innovate more effectively. While challenges remain regarding material limitations and quality control, the benefits far outweigh the drawbacks. As industries continue to embrace this technology, the potential for improved efficiency and cost savings will drive further advancements. The future of rapid prototyping looks promising as it paves the way for groundbreaking innovations across various sectors. Embracing these changes will undoubtedly lead to a more dynamic and responsive approach to product design and manufacturing.