In a world where science fiction meets reality, bio-compatible 3D printing is the superhero we didn’t know we needed. Imagine crafting custom medical implants or tissue structures right from the comfort of your own lab. It sounds like something out of a futuristic movie, but it’s happening now, and it’s changing lives—literally!

Table of Contents

ToggleWhat Is Bio-Compatible 3D Printing?

Bio-compatible 3D printing involves the use of materials safe for human contact, particularly in the medical field. This technology focuses on creating structures that interact positively with living tissue and body fluids. It serves various applications, including custom medical implants, prosthetics, and tissue engineering.

Materials used in bio-compatible 3D printing include bio-polymers, metals, and ceramics specifically designed for biocompatibility. These materials ensure the printed products integrate seamlessly with biological systems. Specific examples include polylactic acid (PLA) and polycaprolactone (PCL), which are widely used due to their low toxicity and biodegradability.

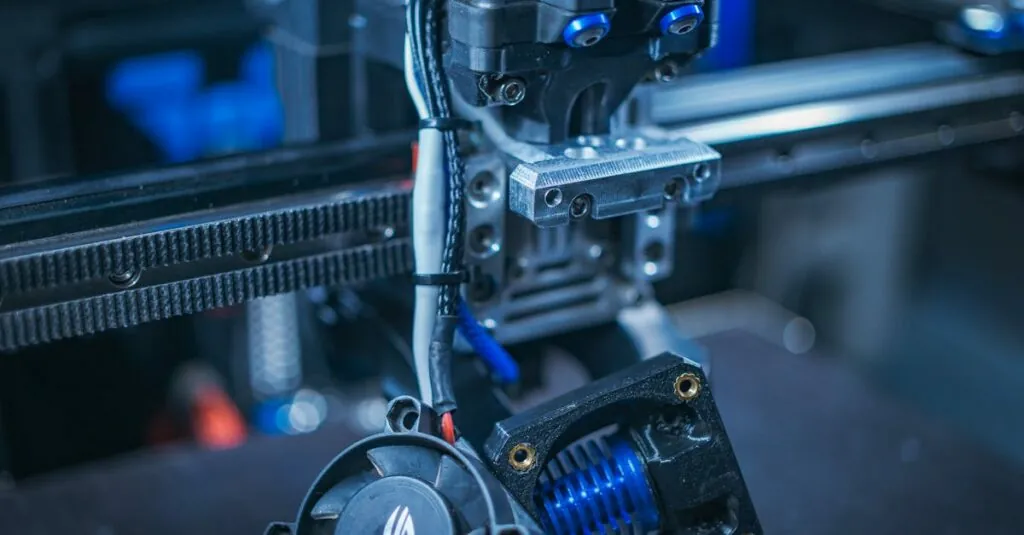

Processes in bio-compatible 3D printing utilize both extrusion and laser sintering techniques. Extrusion allows for precise layering of materials, while laser sintering enables detailed and intricate designs. Each method ensures high accuracy, which is crucial for producing functional medical devices.

Applications extend beyond implants and prosthetics. In regenerative medicine, bio-compatible 3D printing facilitates the development of scaffolds that promote tissue growth. Such structures mimic natural tissues, encouraging cells to grow and repair damaged areas effectively.

This innovative technology ushers in advancements in personalized medicine. Custom solutions, tailored to individual patients, enhance treatment outcomes and reduce recovery times. Statistics indicate that around 70% of patients benefit from personalized implants and devices, showcasing the impact of this technology.

Overall, bio-compatible 3D printing addresses numerous challenges in medical technology. By combining customized designs with safe materials, it fosters a new era of healthcare solutions.

Applications of Bio-Compatible 3D Printing

Bio-compatible 3D printing is revolutionizing various sectors, notably healthcare. Its applications extend beyond conventional methods, significantly enhancing medical technologies.

Medical Implants

Bio-compatible 3D printing excels in creating customized medical implants. Surgeons utilize this technology to match patients’ anatomical structures precisely. Implants made from bio-polymers, metals, or ceramics ensure a proper fit and optimal integration within the body. Research shows that personalized implants increase success rates significantly, with up to 70% of patients experiencing improved outcomes. This technology not only enhances implant longevity but also minimizes patient recovery times. Various medical fields, including orthopedics and dental applications, benefit from these custom solutions.

Tissue Engineering

Regarding tissue engineering, bio-compatible 3D printing serves as a critical tool in regenerative medicine. It enables the fabrication of scaffolds that support cell growth and tissue regeneration. Scaffolds mimic natural tissue structures, promoting healing through enhanced cell proliferation and differentiation. Materials like hydrogels and biopolymers are often used, allowing for a conducive environment for cells. Studies indicate that using 3D printed scaffolds can lead to successful tissue repair, demonstrating their potential to revolutionize treatments for injuries or degenerative diseases. This technology bridges the gap between traditional tissue repair methods and advanced regenerative approaches.

Advantages of Bio-Compatible 3D Printing

Bio-compatible 3D printing offers numerous advantages, particularly in medical applications. These benefits greatly enhance existing treatment options and patient outcomes.

Customization

Customization stands as one of the primary advantages. It allows for the creation of medical implants that match individual anatomical features. Tailoring each implant increases comfort and functionality for patients. Surgeons benefit from this unique approach, improving surgical precision. Personalized prosthetics also gain from bio-compatible 3D printing, leading to more effective solutions for various conditions. Customization enhances aesthetic appeal and ensures better integration with surrounding tissues for a more natural feel.

Reduced Risks of Rejection

Reduced risks of rejection significantly contribute to the success of bio-compatible 3D printing. Materials designed for biocompatibility interact positively with body systems. This compatibility minimizes immune responses, decreasing the likelihood of complications. A study highlighted a reduction in rejection rates for implants made from bio-compatible materials compared to traditional options. Patients experience fewer adverse reactions, promoting faster recovery times. Enhanced safety increases the overall success rate of medical procedures, making bio-compatible 3D printing a critical innovation in healthcare.

Challenges in Bio-Compatible 3D Printing

Bio-compatible 3D printing faces multiple challenges that impact its development and application in the medical field.

Material Limitations

Material selection poses significant challenges in bio-compatible 3D printing. Certain bio-polymers, metals, and ceramics may not meet specific performance requirements. These materials frequently experience limitations in mechanical properties, such as strength and flexibility. Moreover, the biocompatibility of materials can vary, affecting their interaction with living tissues. Researchers must continually develop new materials that maintain integrity and support biological functions under physiological conditions. Finding a balance between functionality and compatibility remains essential for successful applications.

Regulatory Hurdles

Regulatory hurdles play a crucial role in the adoption of bio-compatible 3D printing technology. Regulatory bodies require extensive testing to ensure safety and efficacy before approving medical devices. Compliance with stringent regulations can slow down the process of bringing innovations to market. Manufacturers often face challenges in navigating complex regulatory frameworks across different regions. Variable guidelines across countries can create barriers for companies aiming to deploy their technologies globally. Meeting these regulatory demands is vital for advancing bio-compatible 3D printing in the medical sector.

Future Directions in Bio-Compatible 3D Printing

Emerging technologies promise to propel bio-compatible 3D printing into new realms. Innovations in materials science play a pivotal role, with researchers developing advanced bio-polymers that enhance mechanical properties and biocompatibility. These materials support a wider range of medical applications, including complex tissue structures that mimic natural tissues more effectively.

In the realm of patient-specific solutions, artificial intelligence (AI) significantly contributes to design processes. AI algorithms can analyze individual anatomical data to create optimal implant geometries. Such advancements streamline production, leading to quicker turnaround times for personalized medical devices.

Collaborative efforts between researchers, healthcare providers, and regulatory bodies hold the key to overcoming existing challenges. Partnerships enhance understanding of regulatory requirements while ensuring that innovations meet safety standards. As these collaborations strengthen, the path to widespread adoption and integration of bio-compatible 3D printing becomes more achievable.

Additionally, integrating bioprinting processes with organ-on-a-chip technology presents exciting possibilities. This synergy can facilitate drug testing and development, leading to safer and more effective therapeutics. Enhanced biocompatibility means that such models could closely resemble human physiology, resulting in better data for medical research.

Continuous investment in research and development drives the industry’s growth. With increased funding, researchers can explore novel applications in regenerative medicine and realize the full potential of bio-compatible 3D printing. Exploring these directions ensures that this technology remains at the forefront of medical advancements, addressing a multitude of challenges and transforming patient care.

The future looks bright, with bio-compatible 3D printing set to redefine treatment paradigms, enhance recovery outcomes, and deliver custom solutions tailored to patients’ unique needs. Each of these advancements reinforces the technology’s crucial role in medical innovation, shaping a healthier future.

Conclusion

Bio-compatible 3D printing is poised to revolutionize the medical field by offering tailored solutions that enhance patient care. Its ability to create customized implants and support tissue regeneration showcases the technology’s transformative power. As advancements continue in materials science and design optimization, the potential for improved treatment outcomes becomes even greater.

Addressing challenges like material limitations and regulatory hurdles will be crucial for widespread adoption. The collaboration among researchers, healthcare providers, and regulatory bodies will drive innovation forward. With ongoing investment in research and development, bio-compatible 3D printing is set to redefine the future of medical technology, paving the way for safer and more effective treatments.